Unsaturated Resin / Paint Equipment

According to customer requirements, we can customize reaction kettles and complete sets of synthesis equipment for the synthesis of various resins and lotion, mainly including phenolic resin, epoxy resin, acrylic resin, polyurethane, saturated resin, unsaturated resin, paint equipment and various water-based lotion synthesis equipment. When providing synthesis equipment and complete production lines, we will achieve automatic control of temperature, pressure, monomer and additive addition time based on user specific process requirements. Suitable heating, cooling, and stirring methods will be selected for different material characteristics and processes to ensure effective control of the reaction process and achieve maximum conversion efficiency.

Product features: 1. Vacuum feeding, safe and convenient; 2. The temperature control system is stable and reliable in heating; 3. The automatic control system is executed accurately according to the process requirements; 4. The main reactor is strictly made according to standards, ensuring safety and reliability.

The mixing device is driven by the motor reducer power unit, and the mixer (various mixing forms such as blade, anchor, frame, and dispersed disc) rotates in a fixed direction; During the rotation process, the material is driven to rotate axially and radially. The materials in the reaction vessel exhibit both axial and circumferential movements, resulting in several forms of stirring, including shear stirring and diffusion stirring. Can effectively stir and mix materials quickly. The dispersing disc operates at high speed, causing the material to flow in a circular pattern, generating strong vortices that spiral down to the bottom of the vortex. Strong shear impact and friction occur between particles, achieving rapid dispersion and dissolution. The mixing plate generates good radial force through circular motion, accelerates material circulation, and improves dispersion efficiency.

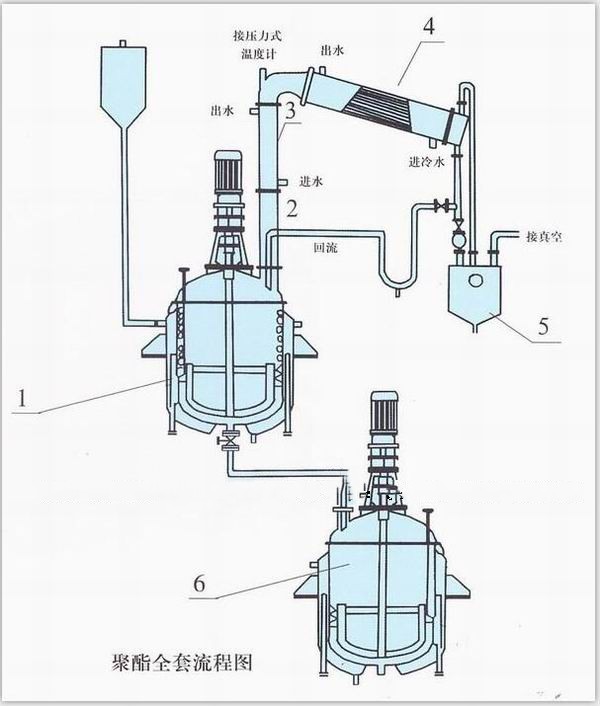

The complete set of resin equipment is used to produce key equipment such as unsaturated polyester resin, phenolic resin, epoxy resin, ABS resin, and paint. The complete set of equipment consists of a reaction kettle, a vertical fractionation column, a vertical condenser, a horizontal condenser, a water storage tank, an oil overflow tank, a high-level tank, a dilution kettle, pipelines (for the dilution kettle), a vacuum unit, etc. The contact parts between the entire set of equipment and materials are all made of stainless steel.

1-Reactor;2-Vertical fractionation column;3-Vertical condenser;

4-Horizontal condenser;5-Shrinkage tank;6-Dilution kettle.

| Part name | Volume and size | |||||||

| Reactor(L) | 50 | 100 | 300 | 500 | 1000 | 2000 | 3000 | 5000 |

| Vertical fractionation column | DN70x460 | DN100x500 | DN150x560 | DN150x750 | DN200x790 | DN200x1000 | DN250x1200 | DN300x1200 |

| High-level tank volume(㎡) | 0.01 | 0.19 | 0.22 | 0.49 | 1 | 1.5 | 2.5 | 5 |

| Horizontal condenser(㎡) | 0.29 | 0.58 | 1.5 | 2.08 | 3.17 | 5 | 12 | 20 |

| Shrinkage tank(L) | 8 | 30 | 50 | 60 | 100 | 120 | 198 | 300 |

| Dilution kettle(L) | 100 | 200 | 500 | 800 | 1500 | 3000 | 4500 | 7500 |