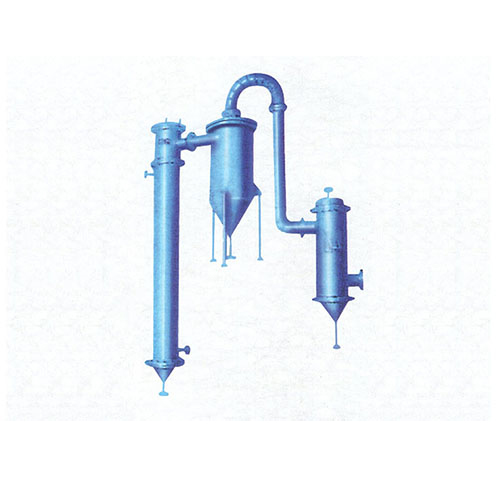

BM Series Thin Film Evaporator - climbing (rising) film evaporator

Thin film evaporator is a type of evaporator characterized by the film like flow of material liquid along the heating tube wall for heat transfer and evaporation. Its advantages include high heat transfer efficiency, fast evaporation speed, and short material residence time, making it particularly suitable for the evaporation of heat sensitive substances.

Hotline:

BM series thin film evaporator unit consists of three components: evaporator, vapor-liquid separator, preheater, and a simple separator. The evaporator is a rising (climbing) film tube heat exchanger. This evaporator has the characteristics of high production capacity, high efficiency, and short heating time of materials, and is suitable for the concentration of dilute solutions in industries such as pharmaceuticals, food, and chemicals. The contact parts between this equipment and materials are made of stainless steel, which has good corrosion resistance, durability, and meets the requirements of pharmaceutical hygiene.

| Model | 2.2㎡ | 5.5㎡ | 8㎡ | 12㎡ | 16㎡ | 20㎡ | 30㎡ | 40㎡ | 60㎡ |

| Evaporation area(㎡) | 2.2 | 5.5 | 8 | 12 | 16 | 20 | 30 | 40 | 60 |

| Preheating area(㎡) | 1 | 2.17 | 4 | 6 | 8 | 10 | 15 | 20 | 30 |

| Steam pressure(MPa) | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Vacuum degree(KPa) | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Evaporation capacity(L) | 140 | 350 | 550 | 850 | 1400 | 1500 | 2100 | 2800 | 4200 |

| Energy consumption(kg/h) | 155 | 385 | 605 | 935 | 1550 | 1650 | 2310 | 3080 | 4620 |

| Weight(kg) | 300 | 520 | 750 | 1020 | 1250 | 2300 | 2950 | 4500 | 5700 |

| Overall dimension(m) | 2x0.85x3.5 | 2.3x0.8x3.5 | 2.7x0.95x4.5 | 2x0.85x3.5 | 2.9x0.95x5.2 | 2.8x1.4x5.3 | 3.8x1.8x6.05 | 1.2x1.8x5.05 | 5x2x5.7 |

Previous:None

Next:None