The core data of this article: the market segment structure of coating resins

1. Classification of coating resin

Coatings are generally composed of four basic components: film-forming substances, pigments, solvents and additives (additives), coating resin is one of the coating film-forming substances, it is the main substance that makes the coating firmly adhere to the surface of the coated object to form a continuous film, is the basis of the coating, determines the basic characteristics of the coating.

Coatings with synthetic resin as the main film-forming material are better than oil coatings and natural resin coatings in terms of mechanical properties, decoration and protection. Since the advent of phenolic paints in 1909, synthetic resin paints have evolved rapidly. There are many varieties of synthetic resin coatings, and there are usually two ways to classify them:

——Classification according to the main film-forming substances

According to the classification of film-forming substances, coating resins mainly include polyurethane resins, epoxy resins, alkyd resins, acrylic resins, phenolic resins, etc.

——Classification according to the dispersion medium used for coatings

According to the classification of dispersion media for coatings, coatings can be divided into three categories: solvent-based, water-based and solvent-free. The output of solvent-based coatings is the largest, and the use is wide, but due to the need to consume a large number of organic solvents and pollute the environment, it is gradually replaced by high-solid coatings, water-based coatings, powder coatings and radiation-curing coatings, and sometimes these types of coatings are called low-pollution, resource-saving, energy-saving coatings, which are new varieties in coating products, and the resins used in different varieties have their own characteristics, which are classified as follows:

Ⅰ. Water-based paints:

Water-soluble coatings: coatings made of water-soluble phenolic resins, amino resins, alkyd resins, epoxy resins, and acrylic resins are usually introduced into a certain amount of carboxyl groups in the resin molecules during the production of resin. This resin reacts with ammonia or organic amines to form ammonium salts that are soluble in water, which becomes a water-soluble resin.

Water-based coatings Water-dispersible coatings: one of the major types of latex coatings is the resin generated by emulsion polymerization, and the particle size of the dispersion formed in water is 0.05~1pm. Styrene-butadiene latex coating is the earliest varieties of industrial production, often used for interior wall coating, in the late 60s, acrylic latex coating developed rapidly, mainly cool acid vinyl - acrylic, styrene acrylic and pure acrylic three series, all have good decoration and weather resistance, mainly used for building coatings.

Ⅱ. High solids coatings:

Generally refers to those in the adjustment to the construction viscosity, the composition of the solid component content is still more than 50% of the coatings, the main varieties are amino alkyd resin, amino-acrylic resin, high solid coatings acrylic acid-polyurethane, polyester and epoxy resin and other high-solid coatings, the coating manufacturing and coating construction are close to ordinary solvent-based coatings, but the resin molecular weight is required to be low, the molecular weight distribution is narrow, the glass transition temperature is low, and the solubility is good.

Ⅲ. Powder coatings:

There are two categories of resins for powder coatings: thermoplastic resin and thermosetting resin, Polyethylene, polypropylene, polyvinyl chloride, polyamide and other powder coatings are the main varieties of thermoplasticity, but their application is limited due to the poor gloss, leveling, mechanical strength and adhesion of the powder coating film. The most widely used thermosetting epoxy, polyester, epoxy-polyester, acrylic resin powder coating, the performance is better than that of thermoplastic powder coating.

Ⅳ. Radiation curable coatings:

Under the action of radiant energy, the synthetic resin coating cured into film is divided into ultraviolet curing coating and electronic eastern-curing coating, and the former has a larger output. (1) ultraviolet curing coating, that is, the photosensitive agent is decomposed into free radicals by ultraviolet radiation, in order to initiate the polymerization of resin containing unsaturated double bonds into film-forming coatings, which are composed of photopolymeric resins, photosensitizers and reactive diluents, and photopolymeric resins are mainly made of unsaturated polyester and acrylic resins.

2. The status quo of the coating resin market segment

——Summary and comparison of coating resin subdivision products

Each has its own characteristics depending on the resin. The output of alkyd resin coatings is the largest, acrylic resin coatings are the fastest, and the output of amino resin coatings, epoxy resin coatings, and polyurethane coatings is also larger, which are the five major varieties of synthetic resin coatings.

| Dimension | Alkyd | Acrylic resin | Polyvinyl chloride | Epoxy resin | Polyurethane |

| Processability | ★★★★ | ★★★ | ★★★ | ★★ | ★★ |

| Drying speed | ★★ | ★★★★ | ★★★★ | ★★★ | ★★★ |

| Weather resistance | ★★ | ★★★ | ★★ | ★ | ★★★★ |

| Glossy durability | ★★ | ★★★ | ★ | ★ | ★★★★ |

| Stain resistant | ★★ | ★★ | ★ | ★ | ★★★★ |

| Chemical resistance | ★ | ★★ | ★★★ | ★★★★ | ★★★ |

| Price | ★★★★ | ★ | ★★ | ★★ | ☆ |

| Use examples |

Note: Full score ★★★★, ☆ is half a star.

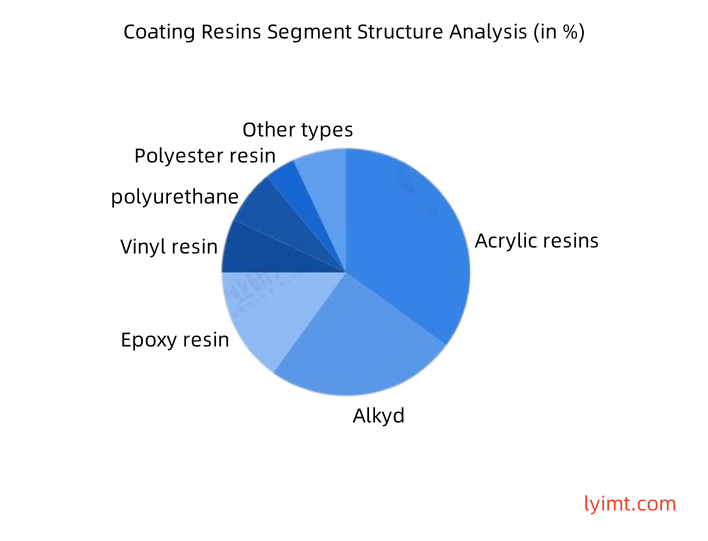

- Acrylic resins, alkyd resins and epoxy resins occupy the main market share

The growth of end industries, such as construction, packaging, general industrial, automotive, marine, aerospace, and furniture, is the key factor driving the growth of the coating resins market. With the rapid development of the downstream industry of coating resin, the application of coating resin has been well expanded, and in the coating resin subdivision products, acrylic resin, alkyd resin and epoxy resin have a total proportion of more than 75% in the coating resin.

3. Resins for non-solvent-based coatings usher in development opportunities

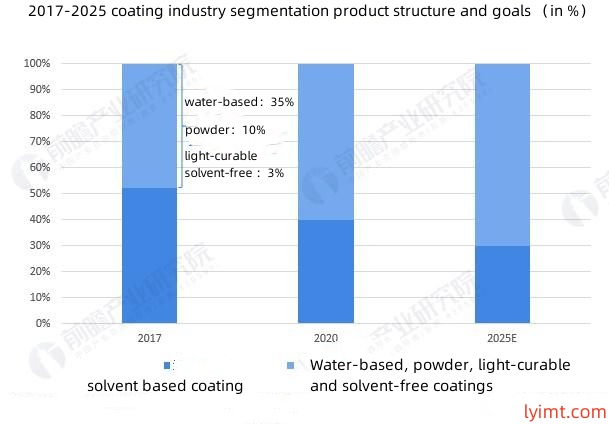

According to the data of the coating industry, in 2017, the proportion of solvent-based paints used in China accounted for 52% of the total paints; water-based coatings and powder coatings accounted for 35% and 10%, respectively; Light-curable and solvent-free coatings account for 3%. In 2022, the State Council issued the "14th Five-Year Plan for Energy Conservation and Emission Reduction", instructing "to promote the use of coatings with low volatile organic compound content" and "by 2025, the proportion of solvent-based industrial coatings should be reduced by 20 percentage points." According to this, the China Coating Industry Association said that at the beginning of the "14th Five-Year Plan", solvent-based coatings accounted for about 40%, and other coatings accounted for 60%; By 2025, the proportion of solvent-based coatings will be reduced to 30%, and resins for non-solvent-based coatings will usher in development opportunities.